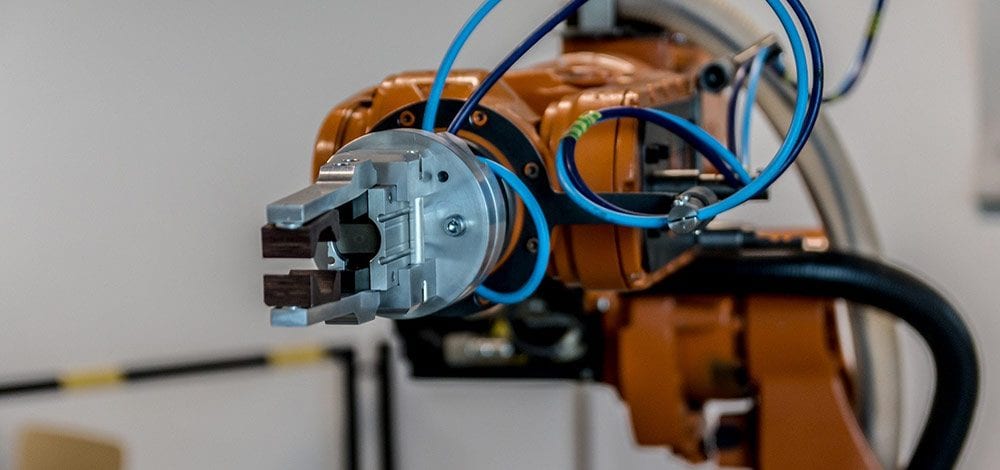

Manufacturers are always seeking greater efficiencies from their processing equipment. Automation has boosted efficiency in assembly and other areas of production, and its use in machining is set to expand rapidly in coming years. There will be more adoption of robotics, including collaborative robots or ‘cobots’ that work alongside humans, taking over repetitive tasks, such as tending machines. By minding machines, these robotic helping hands free up employees to add value in other ways, according to specialists such as Universal Robots.

However, advances in the design of a product and manufacturing process, and the use of new materials in construction, often bring increased complexity and other machining challenges. Accommodating these trends, while still providing the enhanced efficiency required, is no easy task.

This is where the latest computer numerically controlled (CNC) machining and other advanced tooling technologies are coming into their own. Examples include techniques such as low-pollution machining (LPM), high-speed machining (HSM), and high-precision machining (HPM), from equipment suppliers such as global engineering technology specialist Renishaw.

Industry 4.0 capitalizes on machining technology

Industry 4.0 factories make full use of these new approaches to manufacture, especially when they are combined with IMS, exploiting advanced process control and sensor technologies for predictive maintenance and remote diagnostics. In this interconnected world, the ability to gather and analyze all relevant data enables the factory floor and management suite to make better, faster decisions, improving yield and speeding up production, according to machine specialist Mazak. The result is greater productivity and better-quality products with less machine downtime.

Other techniques, such as low-vibration machining (LVM), provided by CNC machine suppliers such as Citizen Machinery, are also having a big impact on the sector. The low-frequency vibration technology developed by the industrial equipment supplier, which is headquartered in Japan with UK bases, increases performance, while improving levels of surface finish and chip control. Cutting trials both in Japan and Europe demonstrated significant improvements to cutting efficiency, not only on exotic materials, but also on difficult-to-cut ferrous and non-ferrous materials, obviating the need for integrated high-pressure coolant systems and fume extraction in some cases.

New materials call for new approaches

Titanium and nickel-based alloys, and CFRPs, are among the new materials that are testing the capabilities of conventional machining methods. These can result in high scrappage rates, reduced tooling life and increased power consumption for manufacturers. But CNC machine specialists have responded by developing new designs, types of tooling – for example, exploiting advances in tool coatings – and innovative approaches to machining that increase efficiency and reduce energy consumption.

One such innovation is trochoidal milling, promoted by machine tool specialist Sandvik and others, and used in the aerospace sector in particular. Trochoidal milling, in which the cutting tool creates a slot wider than the tool’s cutting diameter, is an optimized method of machining Inconel (a family of austenitic nickelchromium-based superalloys) and titanium alloys used in gas turbine fan blade construction. It decreases cutting forces, reduces heat generation, while providing greater machining accuracy, faster cycle times and longer tool life.

Combination is key

These machining techniques are often combined with other technologies such as cryogenic machining, which uses liquid nitrogen (LN2) to freeze cutting tools. Another is minimum quantity lubrication (MQL), in which lubrication is concentrated on the cutting tool instead of flooding the whole area, thereby reducing lubricant and energy use. US aerospace company Lockheed Martin has invested in a number of cryogenic CNC machines for machining titanium alloys used in the construction of its F-35 stealth multi-role fighter jets. The use of 5ME’s patented technique increased cutting speed by more than 50% while improving surface integrity and part quality.

CNC machine manufacturers are continuously refining and developing advanced machining techniques. These are not only essential in exploiting alternative materials in manufacturing, but also to enhance efficiency and sustainability in the programmable and data-driven smart factories of the future.

For more trends in Industry 4.0, download your copy of “Re-tooling industry for the digital age” here:

No Comments